SBC Innovation: One (Centrifuge) Spin to Rule Them All

By Dianne Geary and Tho Pham, MD

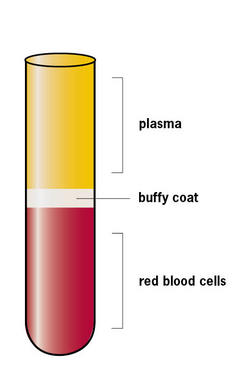

When a whole blood donation gets to lab, it goes for a spin in a centrifuge. From a whole blood unit, Stanford Blood Center (SBC) can then potentially get three products: packed red cells, plasma and buffy coat.

Red cells and plasma products are used for transfusion, while buffy coats are considered byproducts. Here at SBC, buffy coats are made available for research customers.

Buffy coats are enriched with white blood cells, and many scientists depend on this valuable resource to continue their investigative endeavors. SBC receives around 30-50 requests per day. However, a recent increase in the centrifuge speed at which we were processing our whole blood units, while creating a high quality product for plasma, was too fast for making the buffy coats needed to fulfill this need. We needed to create a process in which we could create the priority plasma products needed while fulfilling our research customers’ needs for buffy coats.

In September 2015, collaboration among multiple departments within SBC questioned the possibility of manufacturing both buffy coats and plasma from one whole blood unit. We investigated the machines (component separator, CS) used to process the bags after centrifugation. After centrifugation, the CS expresses different components into different bags. We figured we could reprogram the CS settings to isolate all three components appropriately without changing the centrifuge settings.

We tested numerous programming parameters on the CS. We rolled up our sleeves and systematically experimented with various parameters for weeks until we succeeded: we obtained good buffy harvests and were still able to produce transfusable plasma products. We implemented this new manufacturing process in December 2015.

With this collaboration we have accomplished: (1) increased buffy coat production allowing us to fulfill growing researcher demands, (2) increased production of plasma to satisfy the growing hospital demands, (3) streamlined the manufacturing process.

This was an excellent example of the innovation that occurs at SBC. We are collaborative, and by that collaboration we come up with new methods and ideas that can positively affect the entire organization.

For more about out research products and services, visit: http://stanfordbloodcenter.org/research/products_services.php